Motor Load Types

In order to make a correct selection of a VSD unit for an application, the load type and the demand of the driven system needs to be established. The load demand is achieved by changing the speed of the motor driving the system. Motor torque /Speed characteristic are very important, because the motor provides the torque that the load requires and not the VSD.

VSD (Inverter) only provides speed change and the current to drive the motor. So the sizing of the motor to provide power and torque and rated speed is critical. Then based on the selected motor and load type then a VSD can be selected.

Important factors to consider selecting motors:-

- Variable load or Constant?

- Rapid acceleration

- Accelerating torque requirement?

- Duty Cycle? Continuous or repeated at Intervals?

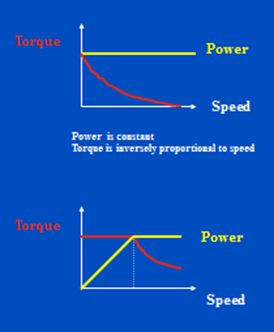

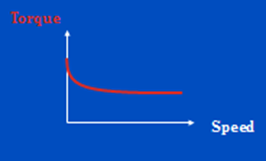

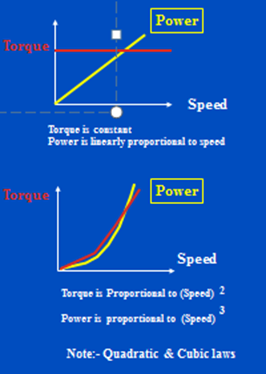

- Torque / Speed Curves.

- Motor KW rating.

- Motor full load current.

- Variable load or Constant.

- Starting torque.

- Accelerating torque requirement.

Constant load types for fixed torque & volume

Typical applications:-

- Conveyors - Consider Overload capacity for starting on load.

- Screw Compressors

- Hoist applications

Variable load

Typical applications:-

- Centrifugal Fan & Pumps

Fixed Torque and Volume